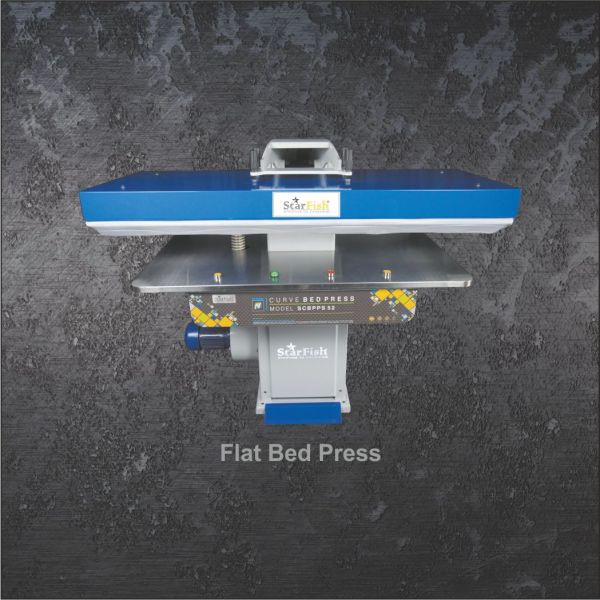

Flat Bed Hot Head Laundry Press-Steam 5x2 Ft SFBPS 52

- Pneumatically Operated

- Bigger Head Covered with Teflon sheet and Bigger Bed padded with sponge stuffing for the finest forcing of flat linen.

- Our created machines of Flat Bed Press under the brand name of Star Fish.

Details

What is flatbed iron?

The horizontal design of these ironing machines ensures exceptional ironing results of the highest quality: They are widely used for ironing items such as bed sheets, curtains, and towels in schools, hotels, hospitals, and other settings. These machines are remarkably efficient, consuming minimal enetgy wie delivering a crisp and flawless finish.

Flat Bed Press:

This machine comprises two beds: a fixed bed called the "BUCK" and a movable bed called the "HEAD. "The HEAD is equipped with springs for flexibility, while the BUCK remains stationary. The BUCK is covered with a soft mat made of fabric, blanket or silicon rubber. The interlining and garment components are first positioned on the BUCK. Upon activating the switch, the HEAD moves downward, applying pressure to the components(interlining).

The HEAD is responsible for applying temperature after a specific duration, it moves back up. Optionally, the suction chamber extracts air from the BUCK. The heating system can be either electrical or steam based. This machine allows for pre-setting of application temperature, pressure and time, ensuring precise fusing conditions and increased production within a given time frame. An air suction system, operated by a foot switch, facilitates faster production. Many machines have timers and programmable controls, enabling superior fusing quality.

| Motor Brand | Specially Designed by us |

| Volt | 415/3Ø or 220/1Ø |

| Motor Speed Rpm | 2880 |

| Perforated Sheet | Pneumatic Piston |

| Table Cloth | Imported Polyster Fabric |

| Table Foam | Silicon |

| Heater (Optional) | Immersed with Thermic Fluid Oil |

| Temperature | 0-140° |

| Control Panel | By Switches |

| Pedal | Limit Switch |

| Emergency Switch | Push Button |

| Body | Mild Steel |

| Table Head | Mild Steel |

| Table Bottom | Mild Steel |

| Heating Base | Stainless Steel 304 Grade Plate |

| Heating Shell | Mild Steel |

| Perforated Bottom | Mild Steel |

| Perforation | Turret Punch Press |

| Pneumatic Piston | Stroke 160mm |

| Spring | Helical Expansion |

| Side Cover | Mild Steel |

| Pedal Base Frame | Mild Steel |

| Nuts, Bolts And Connectors | Mild Steel |

| Cutting | CNC |

| Bending | CNC |

| Welding | Laser/MIG/TIG |

| Finishing | Powder Coated |

| Logo | Starfish Engraving with LED Lights |

| Model | SFBPS 52 |

| Pressing Type | Flat Bed |

| Table Size in mm | 1500 x 600 |

| Suction Area in mm | 1500 x 600 |

| Live Steam | Available |

| Heating Type | Steam |

| Head Movement | Automatic |

| Over All Dimension | 1500 x 1200 x 1400 |

| Motor Power in Kw | 0.55 |

| Steam Consumption Kg/Hr | 20 |

| Steam Pressure in mpa | 0.4 - 0.6 |

| Air Pressure in mpa | 0.4 - 0.6 |

| Foundation | Not Required |

| Net Weight in Kg | 350 |