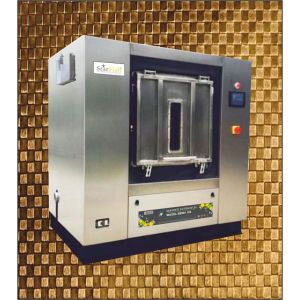

Industrial Tumble Dryer S.S Steam 100 Kg STDSS 100

- Biggest Door

- More loading capacity

- Less Steam

- Quick Drying

- More Durability

- Less Maintenance

Details

Known by various names such as Clothes Dryer, Drying Machine, and Tumble Dryer, this appliance utilizes a mechanism of action that efficiently removes moisture from loads of clothing and textiles. With its advanced features and reliable performance, the Industrial Drying Tumbler is an excellent choice for professional and industrial applications

The Industrial Drying Tumbler is a high-quality appliance designed to effectively remove moisture from various types of clothing and textiles. Constructed with a durable stainless steel inner cylinder and a painted outer body, this tumbler offers superior performance and longevity. Additionally, an option for a stainless steel outer body with live steam arrangements is available, ensuring resistance to peeling and rusting.

Featuring a front-loading facility and a spacious door opening, this tumbler allows for easy and fast loading of garments. Its open pocket design, combined with a reversible feature and a cool-down function, further enhances convenience and efficiency. The digital temperature controller guarantees precise temperature control, with the display indicating the temperature in Centigrade.

Equipped with dual motors and a belt drive system, this tumbler ensures smooth and reliable operation. The perforated basket prevents snagging and sagging of garments, while a safety main door switch adds an extra layer of protection. Notably, the inclusion of an "Anti-Wrinkle Safety Rumble" mechanism effectively minimizes excessive wrinkling during the drying process.

This tumbler is also an energy-efficient choice, thanks to its Double Wall Glass Wool Technology PUF insulation. It is available in various heating options, including steam, electric, gas, diesel, and thermic fluid. The live steam arrangements, if chosen, allow for quick drying without shrinkage.

To further enhance performance, a bypass assembly is provided, ensuring faster drying times by preventing steam condensate water accumulation. The dynamic balanced aluminum blower effectively matches heating and blowing, maximizing energy utilization and reducing drying time by approximately 25%. Additionally, the steam radiator with copper tubes guarantees enhanced efficiency.

| Motor Brand | Imported |

| Volt | 220 /1Ø or 415/3Ø |

| Drying speed Rpm | 32 |

| Forward/Reverse | Adjustable 0-30 Seconds |

| Heating Type | Electric | Gas | Steam |

| Drying Time in Min | 0-99 min Controlled by PCB |

| Control panel | PCB |

| Temperature | Upto 80º |

| Front Panel | Feather Touch |

| No of Program | 5 |

| Manual Operation | Available |

| Door Open Cut Off | Limit Switch |

| Outer Drum | Mild Steel |

| Inner Drum | Stainless Steel 304 Grade |

| Perforation | Turret Punch Press |

| Side Covers | Stainless Steel |

| Motor Guard | Mild Steel |

| Insulation | Outer Drum Covered by 10mm Thick Ceramic Paper |

| Base Frame | Mild Steel Channel |

| Door | Mild Steel Glass Door with magnetic lock |

| Belt Adjustment | Screw Rod |

| Nuts, Bolts & Connectors | Mild Steel |

| Control Box | Mild Steel |

| Lint | Mild Steel Mesh |

| Cutting | CNC |

| Bending | CNC |

| Welding | Laser MIG/TIG |

| Overall Finish | Matt Finished Stainless Steel |

| Logo | Starfish Engraving with LED Lights |

| Motor Power in kw | 2.5 |

| Blower Motor in kw | 2.5 |

| Heating Type | Steam |

| Heater in Kilowatt | - |

| Consumption Per Hour | 100 Kg |

| Foundation | Not Required |

| Weight in Kgs | 1200 |

| Model | STDSS 100 |

| Dry weight in Kg | 100 |

| Drum size in mm | ø1450 x 1150 |

| Drum Volume in litres | 2000 |

| Liquor Ration | 1:20 |

| Overall Dimension in mm | 1650 x 1930 x 2410 |

| Door Open in mm | 1200 |