Perc Dry Cleaning Machine Auto MS - Premium 8 - 10 Kg SMADP 8

- All dimensions are in millimeters.

- Air compressor required.

- Foundation required.

- Our machines are used not only in laundry units, but also in hotels, institutions, schools, and college hostels, among other places, where bulk quantity garment dry cleaning is required.

- Due to continued improvement, the company reserves the right to change the specification and model without prior notice.

Details

Dry cleaning is any cleaning process for clothing and textiles using a solvent other than water. Dry cleaning still involves liquid, but clothes are instead soaked in a water-free liquid solvent (usually non-polar, as opposed to water which is a polar solvent). Tetrachloroethylene (perchloroethylene), known in the industry as "perc", is the most widely used solvent. Alternative solvents are 1-bromopropane and petroleum spirits. Most natural fibers can be washed in water but some synthetics (e.g., viscose, lyocell, modal, and cupro) react poorly with water and should be dry-cleaned if possible.

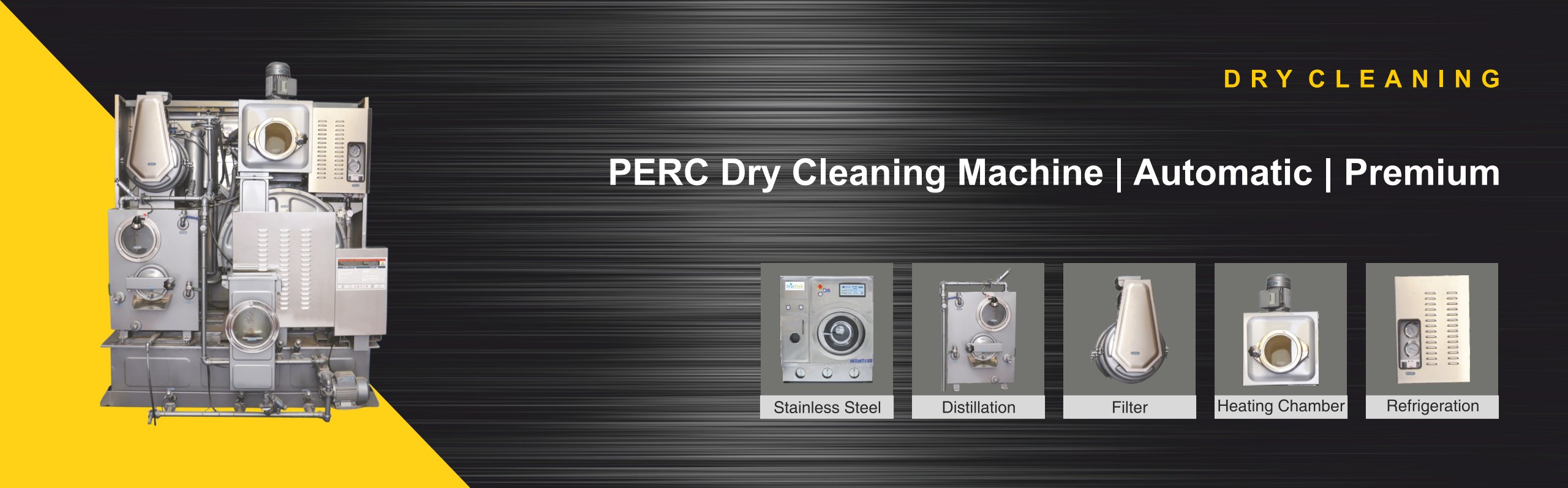

The machines are made of imported high quality steel, with an oil storage tank at the bottom, a drying passage, and a perchloroethylene-resistant position.

The machines have a German design, with a reasonable structure, a precise workmanship, a fashionable style, and a paint with imported high class auto dope that makes the machines look elegant.

The machines have a heating radiator that speeds up the drying and recovers more solvents with much lower dry cleaning detergent consumption than other similar products.

The machines use high quality spare parts from famous brands, such as electrical materials and appliances, electric appliances, main electric components, valves, transmission parts and cooling system.

The machines have a high quality recycle cooling system that recovers solvents efficiently, reduces pollution, and saves solvent.

The machines are microcomputer-controlled, fully automatic, with a large LCD-display that is easy to understand.

The machines have three bottom tanks that separate clean, dirty and working solvent, prevent solvent mixing, protect the machine and save solvent.

The machines have a centrifugal filter that removes impurities, particles, pigment, ensures clean solvent, prevents dyeing and blockage.

The machines have a drum in stainless steel, made of non-ferrous metals stamping with mold crafted, high-temperature galvanizing technology that is strong and nice.

The machines have a high-speed fan that speeds up the drying and cooling rate.

The machines have a safety door interlock system that protects the operator.

| Motor Brand | Imported |

| Filter Motor | Imported |

| Volt | 415 / 3Ø |

| Washing Speed Rpm | 37 |

| High Extract Rpm | 480 |

| Forward/Reverse | Controlled by PCB |

| Beaters | To improve Cleaning Quality |

| VFD | Adjustable drum rotation 0-37 RPM |

| Washing Time | Controlled by PCB |

| Extraction Time | Controlled by PCB |

| Control Panel | PCB |

| Drying Temperature | 0-50° Controlled by PCB. |

| Front Panel | Feather Touch |

| Manual Operation | Available |

| Door Open Cut Off | Limit Switch |

| Emergency Switch | Yes |

| Inner Drum | Stainless Steel 304 Grade |

| Outer Drum | Stainless Steel 304 Grade |

| Perforation | Turret Punch Press |

| Back Plate | Stainless Steel |

| Side Cover | Mild Steel |

| Back Cover | Mild Steel |

| Base Frame | Mild steel channel |

| Door | Die cast with Glass |

| Belt Adjustment | Screw Rod |

| Nuts, Bolts & Connectors | Mild Steel |

| Distillation | PUF Insulated Tank with Heater |

| Cooling Compressor | Panasonic/Equivalent |

| Radiator | Copper Tube with Aluminium Fins |

| Filter | Carbon |

| Cutting | CNC |

| Bending | CNC |

| Welding | Laser MIG/TIG |

| Overall Finish | Powder Coated |

| Logo | Starfish Engraving with LED Lights |

| Total Power in kw | 13 |

| Steam Consurnption Kg/Hr | 10 |

| Water Inlet in mm | 25 |

| Drain Outlet inmm | 17 |

| Foundation | Required |

| Weight in Kgs | 1050 |

| Model | SMADP 8 |

| Dry Weight in Kg | 8 - 10 |

| Body Type | Mild Steel |

| Chemical | Perchloroethylene |

| Drum Volume in liter | 145 |

| Liquor Ratio | 1:14 |

| Mode of Heating | Steam Through Electric Boiler |

| Dimension in mm | 1640 x 1200 x 1940 |