Industrial Flat Work Ironer Single Roller Gas 600 MM 2000 mm SFWG6 2000

- Premium Quality Ironing.

- Safe-enabled operation system.

- High efficiency.

- Low consumption of energy.

Details

Ironer has a variable-frequency drive [LS] for speed adjustment.

The customer can adjust speed according to fabric thickness to improve ironing efficiency.

The ironing roller has an 800 mm diameter and is made of stainless steel.

Roller uses galvanization technology to extend its life.

Heating by adopting a stainless steel cylinder presents a good effect.

Maximum touchable area 300 Degree roller circle effectively expands the work area and improves ironing speed, and heat energy and reduces the Running cost.

The roller will run continuously if the drive motor is connected to a gearbox.

The main machine, manufactured by cutting laser machines and welded with high-quality welding, has a beautiful look and runs smoothly.

Precise transmission, quality running, and a long lifespan

High temperatures are not a problem for high-quality iron belts.

Because of its small covering area, a compact structure saves a lot of space.

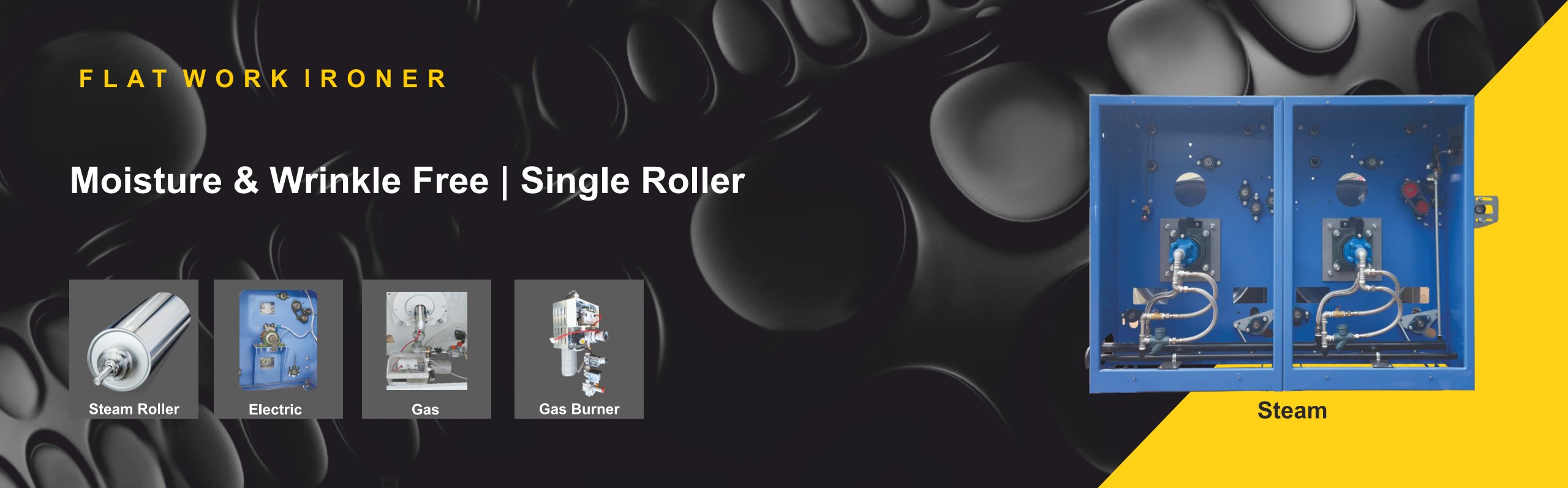

Several types of heating by outside connections—steam, gas, and electric—are optional.

Also, available return feed and rear return, are optional.

| Motor Brand | |

| Volt | |

| Drying Speed Rpm | |

| Drying Time | |

| Control Panel | |

| Front Panel | |

| Temperature | |

| Manual Operation | |

| Ironing Belt | |

| Ironing Belt Width |

| Finger Guard | Door Limit Switch |

| Emergency switch | Yes |

| Steel Brand | |

| Main drum | |

| Main drum construction | |

| Main drum specification | |

| Supporting Rollers | |

| Side Panel | |

| Side Cover | |

| Back Cover | |

| Base Frame | |

| Doors | |

| Motor Belt Ajustment | |

| Ironing Belt Adjustment | |

| Shaft Gland | |

| Nuts,Bolts And Connectos | |

| Control Box & Lock | |

| Mounting Type | |

| Cutting | |

| Bending | |

| Welding |

| Material | |

| Powder coating | |

| Logo |

| Motor Power in Kw | |

| Blower Motor | |

| Heating Type | |

| Heater in Kilowatt | |

| Consumption Per Hour | |

| Foundation | |

| Weight in Kgs |

| Model | SFWG6 2000 | |

| No of Rollers | ||

| Roller Length in mm | ||

| Roller Dia in mm | ||

| Speed of Ironing m/min | ||

| Steam Inlet | ||

| Pressure of Stem Mpa | ||

| Gas Pressure | ||

| Over All Dimension in mm | ||