Industrial Front Loading Washing Machine 35 Kg SFW 35

- Reduce water consumption.

- Minimise steam usage.

- Optimise processing time while increasing loading capacity.

- Enhance durability.

- Decrease reliance on manpower.

Details

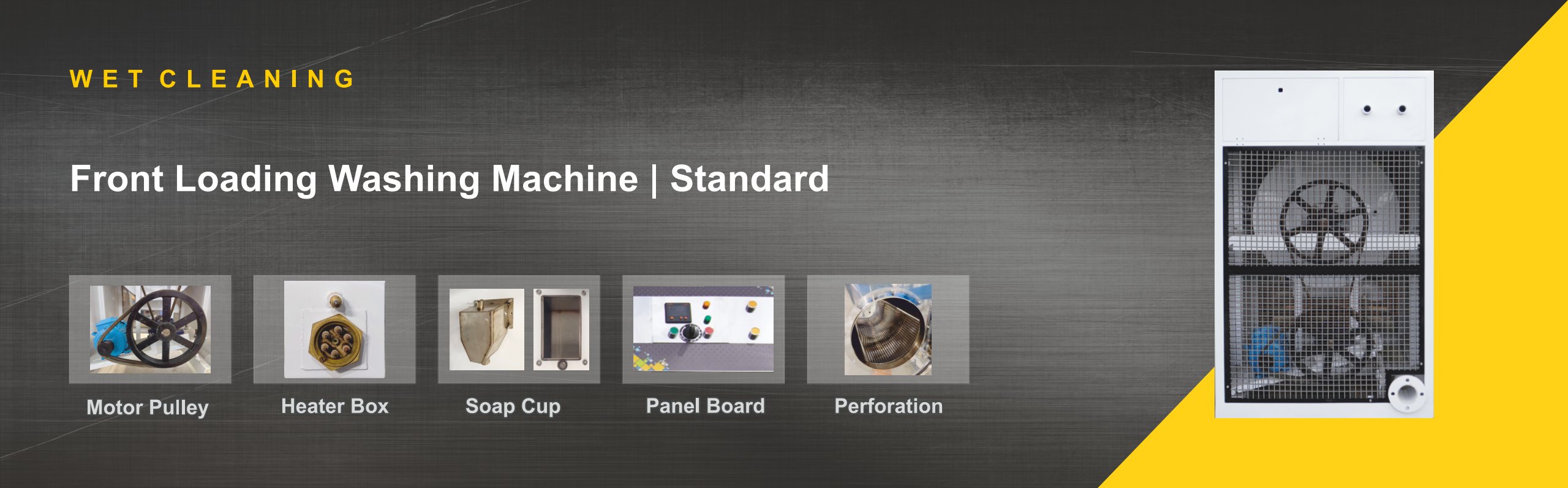

Front-loading washers are mechanically simple compared to top-loaders, with the main motor normally being connected to the drum via a grooved pulley belt and large pulley wheel, without the need for a gearbox.

The action of a front-loading washing machine is better suited to a motor capable of reversing direction with every reversal of the wash basket.

The Front Loading Laundry Machine features a high-quality stainless steel inner and outer basket, with an optional 316 grade for dyeing.

These economically-priced units suit various laundry, textile processing, and dyeing applications.

They are available in Steam, Electric, and Thermic fluid options.

Heating and Water level are controlled through electric and pneumatic solenoid valves (Optional) .

The Door glass allows easy viewing even when the machine is running.

There is an option for variable frequency controlled drive(Inverter) for required cylinder speed.

Specially designed stuffing box filled with gland packing and silicon seals. No chances of leakage.

Our primary objective in designing this machine is to

Reduce water consumption.

Minimise steam usage.

Optimise processing time while increasing loading capacity.

Enhance durability.

Decrease reliance on manpower.

| Motor Brand | ABB/Equivalent |

| Volt | 415 / 3Ø |

| Rpm | 32 |

| VFD(Optional) | Adjustable Drum Rotation 0-32 RPM |

| Forward/reverse | Adjustable 0-60 Seconds |

| Beaters | To improve wash Quality |

| Washing Time | 0-60 min controlled by Timer |

| Temperature | 0-60° Controlled by Digital Temperature Sensors |

| Control panel | Manually Operated Switch Controls |

| Water level | See through Gauge glass |

| Door Open Cut Off | Limit Switch |

| Outer Drum | Stainless Steel 304 Grade |

| Inner Drum | Stainless Steel 304 Grade |

| Perforation | Punching Press |

| Side Cover | Stainless Steel 202 Grade |

| Back Plate | Mild Steel Plate Covered by Stainless Steel 202 Sheet |

| Base Frame | Mild Steel Channel |

| Door | Stainless Steel 304 Grade |

| Belt Adjustment | Screw Rod |

| Shaft Gland | Bearing with Gland Covered by Asbestos Rope |

| Nuts, Bolts And Connectors | Mild Steel |

| Drum and Side panel Joint | By using Asbestos Sheet |

| Control Box | Mild Steel with Knob |

| Safety Mesh | Mild Steel |

| Cutting | CNC |

| Bending | CNC |

| Welding | MIG/TIG |

| Overall Finish | Gloss |

| Logo | Standard Sticker |

| Model | SFW 35 |

| Dry Weight in Kg | 35 |

| Drum Size in mm | Ø920 x 520 |

| Drum Volume in Liter | 345 |

| Liquor Ratio | 01:10 |

| Over All Dimension in mm | 1200 x 1250 x 1630 |

| Door Open in mm | Ø550 |

| Steam Consumption Kg/Hr | 30 |

| Water Inlet in mm | 25 |

| Drain Outlet in mm | 75 |

| Heater in Kilowatt | 9 |

| Foundation | Not Required |

| Weight in Kgs | 500 |

| Motor Power in kw | 1.5 |